The Gack K-150A Shaper

Hugh Sparks

October 5, 2003

http://www.csparks.com

The page describes my adventures with an unusual German shaper. It seems to be my fate to rescue and restore bizarre machines.

The Gack came into my life at a liquidation auction. Like some uninvited creature from a Dr. Suess book, it managed to consume all my spare time for the next 5 months. It was, as usual, a total wreck. I couldn't even attempt a trial run without risking further damage. First I tore it down to nuts and bolts followed by cleaning, painting, and making a few new parts. Details of this process are presented in other parts of the site.

The machine is unusual in several respects: The most striking feature is the ram, which travels from side to side. For this reason, I call it a "lateral shaper."

There is no clapper box. Instead, a "spindle" rotates the tool up and out of the way at the end of the cut so the ram can return leftward to begin another stroke.

Here you will find a discussion of restoration process and the operation of the machine. There are many areas that still puzzle me and I've been unable to locate manuals or any other documentation. If you know anything about this machine or care to offer any opinions, please let me know.

Selections from a poorly-translated German advertisement

Revolutionary design: accurate and clean cuts.

The worked parts can be considered finished for most purposes.

Many uses:

Surfaces, radii, any shapes even with grooves terminating in

round shape at one side, as cutting dies may frequently require

can be machined.

Many attachments and practical clamping devices permitting machining

the entire surface of workpieces without need for reclampling.

Optical measuring devices permitting finishing without scribing and

microscopical observation of the shaping processes.

| Metric (mm) | English (in) | |

|---|---|---|

| Stroke of ram | 0-150 | 0-6 |

| Transverse travel | 160 | 6.25 |

| Automatic feed | 750 x 180 | 0.002-0.018 |

| Vertical travel | 160 | 6.25 |

| Table size | 750 x 180 | 29.5 x 7 |

| Working area | 150 x 160 | 6 x 6.25 |

| Space required | 1000 x 1100 x 1500 | 39 x 43 x 59 |

| Rate | 50, 75, 100 cycles/minute | |

| Horsepower | 3/4 | |

| Weight | 1675 lbs |

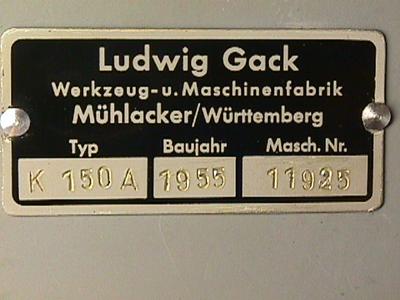

This label is on the left side of the head casting. It sums up just about all I know about the origin of this machine.

The Deutsches Museum in Munich has some kind of archive on the "Ludwig Gack Werkzeug und Mashinen-Fabrik." They will send copies for a modest fee.

I found a small advertisment for the Gack in "The Big Book of Metalworking Machinery." This is a phonebook-sized trade catalog for machinery dealers published by "Zulch & Zulch." in 1972. I got the specifications for the machine and accessories from this source.

Nothing out there on Gacks yet, but here are a few sites with shaper information.

The Artful Bodger has a nice description of a finishing cutter for shapers. This is a very unusual tool. It is mentioned in K.H. Moltrecht's Machine Shop Practice, Vol 2. I made one of these and it works extremely well. It was used to produce the cut shown in the animation section.